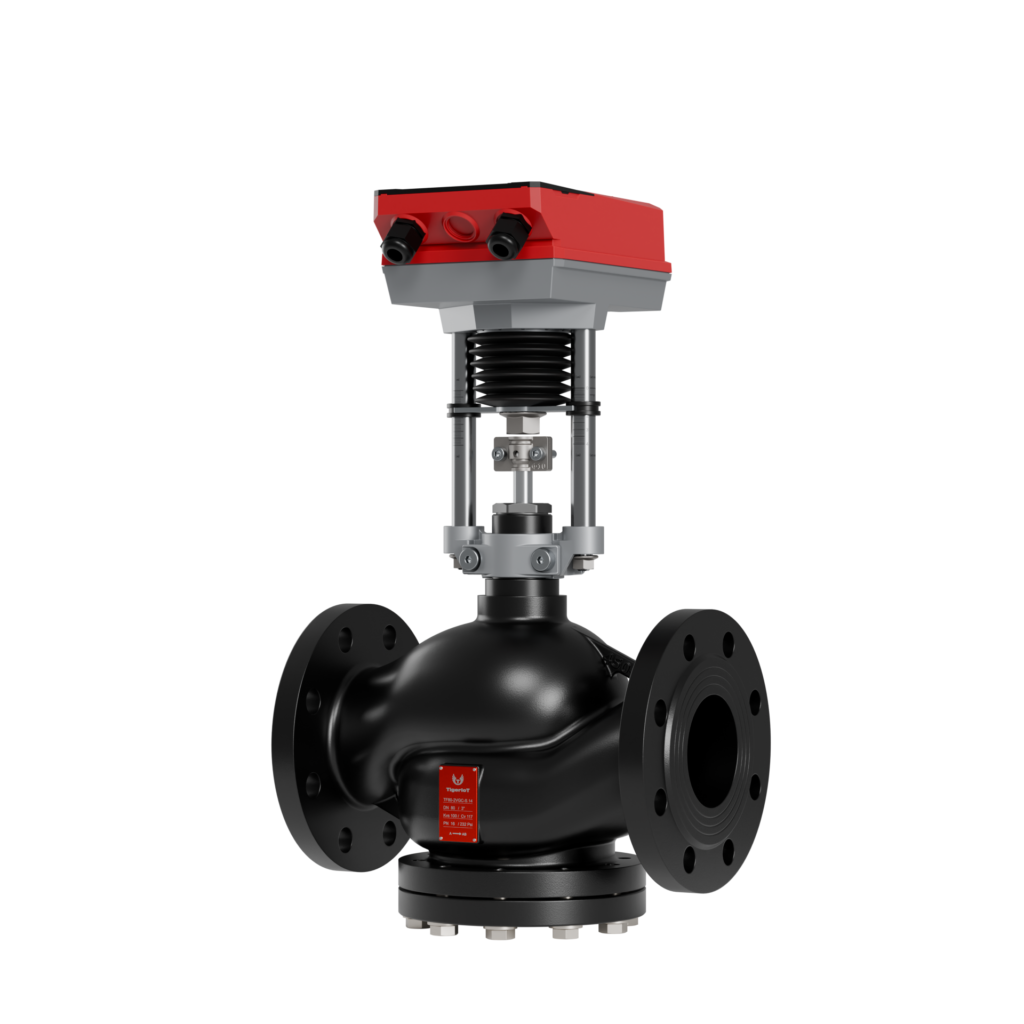

IoT Electric Control Valve

Delivering More Precise Control · Enabling Higher System Efficiency

Upgraded Electric Actuator

600N/ 1000N / 3000N / 5000N

High-Precision Resolution

0.3% high resolution. The maximum valve opening range can be set remotely via the platform.

Manual Operation

Equipped with a mechanical manual override with manual-priority protection. When the handle is engaged, the actuator automatically cuts power to ensure safe manual operation.

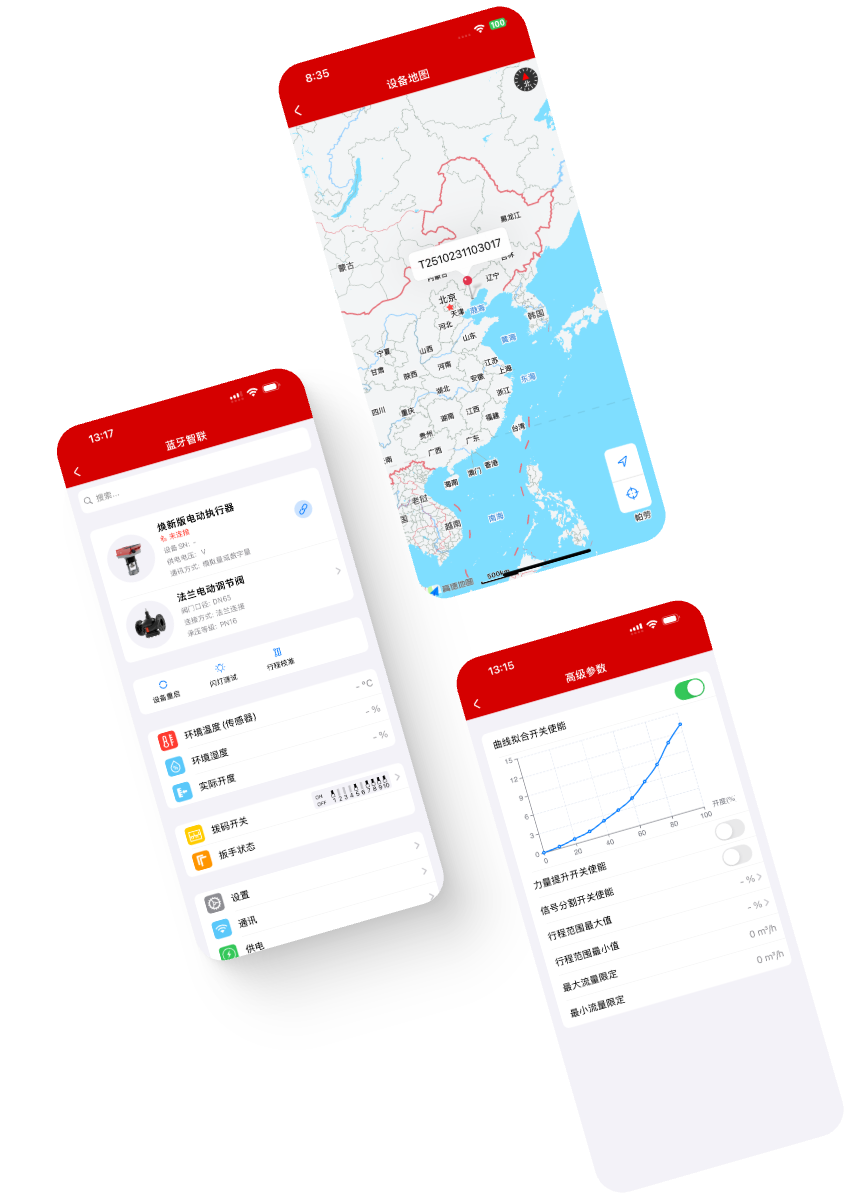

Dedicated Mobile App

A dedicated mobile app enables valve open/close control and multi-parameter configuration. Even during on-site power loss, the app can still read actuator parameters.

5-Year Extended Warranty, Quality Proven Over Time

Industry-leading 5-year full-unit warranty, validated by over 100,000 full-stroke, failure-free operations, providing a solid technical foundation for long-term reliability.

Electronic Local Control

- Top-mounted button operation when powered on

- Automatic stroke calibration

- Easy on-site commissioning

Mobile App, Total Control at Your Fingertips

Fast Bluetooth Connection

Instant plug-and-play via Bluetooth, no wiring or complex configuration required, enabling faster and more efficient on-site commissioning and maintenance.

Real-Time Control & Parameter Configuration

Supports real-time start/stop control, stroke adjustment, and key parameter configuration. Intuitive operation with visualized tuning process improves commissioning accuracy.

Data Synchronization & Historical Records

Operating data is automatically synchronized to the app, supporting historical record queries and comparative analysis for fault diagnosis and performance evaluation.

Field Maintenance-Friendly Design

Clean and intuitive app interface designed around engineers’ workflows, significantly reducing commissioning time and improving on-site operation and maintenance efficiency.

Valve Body

Optimized Control Curve

Equal-percentage control characteristic with a turndown ratio up to 100:1, delivering precise control under both low-flow and high-flow conditions to meet fine process control requirements.

Medium Temperature Range

Industrial refrigerants: −40 ~ 80 °C Chilled / hot water: −10 ~ 130 °C Steam: 2~180 °C/2~250 °C/2~400 °C

Ductile Iron Construction

High-strength ductile iron valve body provides excellent mechanical strength and impact resistance, while ensuring reliable pressure tolerance and dimensional stability.

Powered IoT Electric Control Valve

Multiple Temperature & Pressure Measuring Points

Supports up to 4 PT1000 temperature sensors and 8 RS485 pressure sensors for multi-point data acquisition.

RS485 Remote Control

Equipped with an RS485 communication interface, enabling remote valve control via the Modbus protocol.

Built-in PID Control

Can connect supply/return water temperature sensors and supply/return water pressure sensors, allowing direct temperature-based valve control without external controllers.

Battery-Powered IoT Electric Control Valve

Dual Temperature & Dual Pressure Measuring Points

Supports up to 2 PT1000 temperature sensors (connected to the actuator) and 2 RS485 pressure sensors (connected to the actuator).

Battery Power Supply

Battery box uses a quick-connect plug for fast replacement and easy installation.

NB-IoT Wireless Communication

Low power consumption and easy deployment. Data can be uploaded directly to the cloud platform. Standard external antenna included, 3 m cable length.

Performance Advantages

Balanced Valve Core Design

Effectively reduces the impact of medium pressure on valve opening and closing. Supports a closing pressure differential up to 16 bar, ensuring stable and reliable operation under high ΔP conditions.

Ultra-Low Leakage Sealing Performance

Water valves adopt stainless-steel hard sealing technology, with leakage ≤ 0.01% Kvs. Steam valves use an alloy sealing surface structure, achieving ultra-low leakage ≤ 0.001% Kvs.

Equal-Percentage Flow Characteristic · High Turndown Ratio

Features equal-percentage flow control with smooth linear regulation across the full stroke. Turndown ratio > 100:1, ideal for precise flow control applications.

Low-Noise Operation

Optimized valve core and flow channel design significantly reduce noise and vibration caused by fluid flow, delivering quiet, stable operation for noise-sensitive environments.

Application Scenarios

Air Conditioning Water Systems

Ventilation Systems