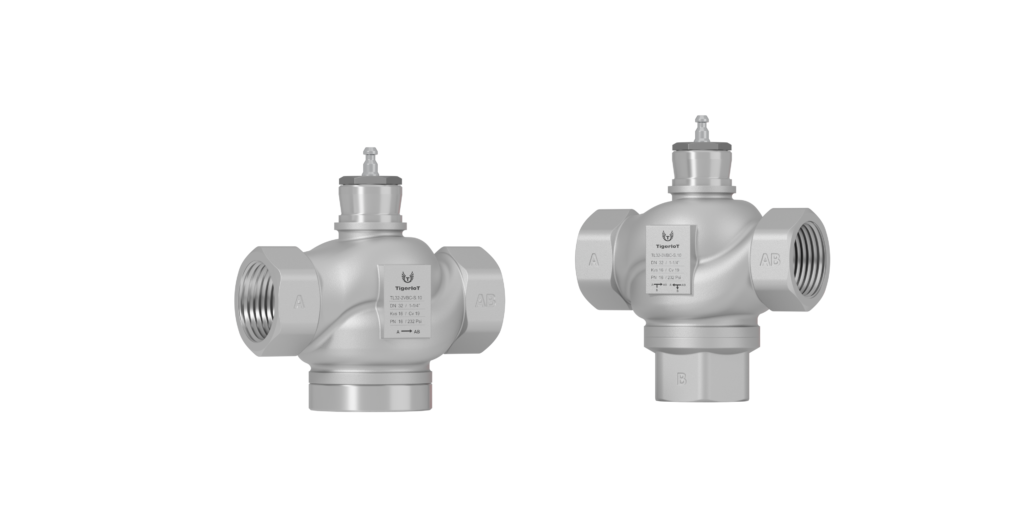

Threaded Electric Globe Control Valve

Designed for Precise Flow Control

Upgraded Electric Actuator

500N / 600N / 1000N

Integrated Control

Combines proportional control and floating control. Supports RS485 communication based on the standard Modbus protocol for remote valve control.

High-Precision Modulating Performance

Optional RS485 interface with modulating sensitivity up to 0.3%, enabling finer and more stable control for demanding applications.

Brushless DC Silent Drive

Adopts brushless DC motor technology for quiet operation, high efficiency, and reliable structure—ideal for long-term continuous operation.

Signal-Loss Safety Protection

Supports signal-loss reset / fail-safe modes. Operating status can be flexibly configured to enhance system safety and reliability.

Automatic Stroke Calibration, No Commissioning

Built-in automatic stroke calibration. Ready for use after delivery or installation—no complex commissioning required, reducing installation and maintenance costs.

Manual Override

Equipped with mechanical manual override for convenient on-site maintenance and adjustment.

5-Year Extended Warranty · Quality Proven Over Time

Industry-leading 5-year full-unit warranty, validated by over 100,000 full-stroke trouble-free operation cycles, providing a solid technical foundation for long-term reliability and peace of mind.

Capacitor Return Actuator

Configurable Return Position

Return position can be flexibly set to fully open, fully closed, or any intermediate position to meet diverse control requirements.

Capacitor-Based Return Design

Built-in high-performance capacitors enable return operation without external power supply, featuring a compact structure and simplified maintenance.

Stable and Reliable Output Torque

Capacitor-stored energy provides stable return torque, ensuring precise and reliable valve operation.

Fast Response, Energy-Efficient Operation

Capacitors release energy rapidly to enable instant valve actuation, reducing energy consumption and improving control efficiency.

Electronic Local Control

- Top-mounted button operation when powered on

- Automatic stroke calibration

- Convenient on-site commissioning and adjustment

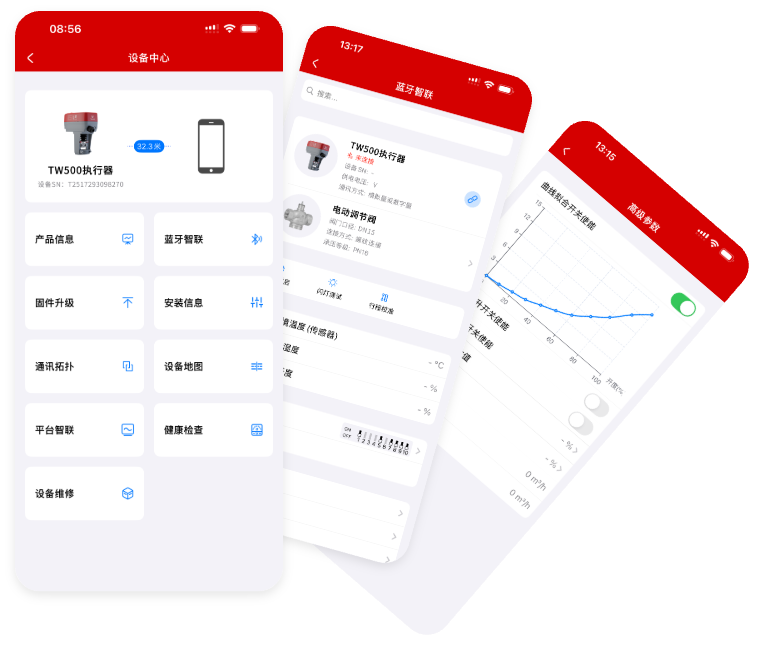

Mobile App · Control Anytime, Anywhere

Fast Bluetooth Connection

Instant plug-and-play via Bluetooth, no wiring or complex configuration required, enabling faster and more efficient on-site commissioning and maintenance.

Real-Time Control & Parameter Configuration

Supports real-time start/stop control, stroke adjustment, and key parameter configuration. Intuitive operation with visualized tuning process improves commissioning accuracy.

Data Synchronization & Historical Records

Operating data is automatically synchronized to the app, supporting historical record queries and comparative analysis for fault diagnosis and performance evaluation.

Field Maintenance-Friendly Design

Clean and intuitive app interface designed around engineers’ workflows, significantly reducing commissioning time and improving on-site operation and maintenance efficiency.

The Rust-Free Era

- Lead-free, eco-friendly design to safeguard water quality

- High hardness and strong corrosion resistance for extended service life

- Clear cost advantages for greater economic efficiency

- Premium appearance with modern aesthetics

Valve Body

Performance Advantages

Balanced Valve Plug Design

Reduces the influence of medium pressure on valve opening and closing, enabling a high shut-off differential pressure of up to 16 bar, ensuring stable and reliable operation even under high differential pressure conditions.

Ultra-Low Leakage Sealing Performance

Water valves adopt stainless-steel hard-sealing technology with a leakage rate ≤ 0.01% Kvs. Steam valves use alloy sealing surfaces, achieving ultra-low leakage rates of ≤ 0.001% Kvs.

Equal Percentage Flow Characteristic · Ultra-High Turndown Ratio

The valve features an equal-percentage flow characteristic, providing smooth and linear control across the full stroke, with a turndown ratio greater than 100:1, ideal for precise flow control applications.

Low-Noise Operating Performance

Optimized valve plug structure and flow path design effectively reduce noise and vibration caused by fluid flow, ensuring quiet and stable operation for noise-sensitive environments.

Application Scenarios

Data Center

Pharmaceutical Plant